Laser Scanning Solutions, Llc. Things To Know Before You Get This

Table of ContentsFacts About Laser Scanning Solutions, Llc. UncoveredLaser Scanning Solutions, Llc. for DummiesThe Best Guide To Laser Scanning Solutions, Llc.The Buzz on Laser Scanning Solutions, Llc.

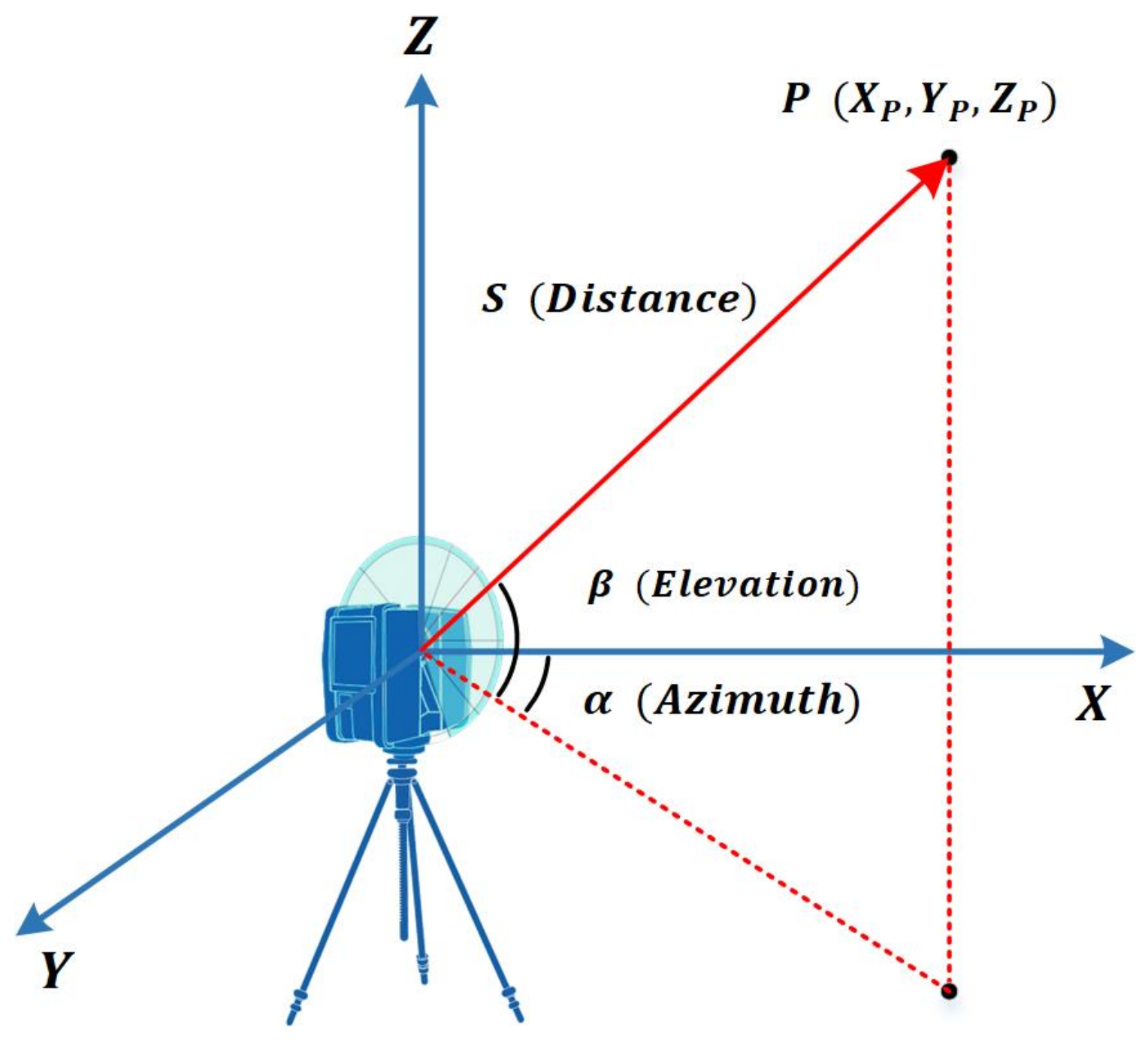

In order to place a laser light beam in 2 dimensions, it is feasible either to rotate one mirror along 2 axes - made use of primarily for slow-moving scanning systems - or to reflect the laser beam of light onto 2 carefully spaced mirrors that are placed on orthogonal axes (https://laserscann1ng.start.page). Each of the 2 level or polygon (polygonal) mirrors is then driven by a galvanometer or by an electric motor specifically

Some applications call for placing the emphasis of a laser beam in three dimensions. This is accomplished by a servo-controlled lens system, generally called a 'focus shifter' or 'z-shifter'. Many laser scanners additionally enable transforming the laser strength. In laser projectors for laser television or laser displays, the 3 fundamental colors - red, blue, and eco-friendly - are integrated in a solitary light beam and afterwards mirrored along with 2 mirrors.

Modern lasers can reduce steel blocks with a thickness of 10 cm and even more or ablate a layer of the cornea that is just a couple of micrometers thick - https://laser-scanning-solutions-llc.jimdosite.com/.

The Main Principles Of Laser Scanning Solutions, Llc.

That card transforms the received vector data to motion info which is sent out to the scanhead. This scanhead contains 2 mirrors that are able to deflect the laser beam of light in one degree (X- and Y-coordinate). The 3rd dimension is - if needed - recognized by a details optic that is able to move the laser's prime focus in the depth-direction (Z-axis).

For these cases it is important that the laser has as little a focal factor as feasible (lidar 3d scanning). For enhanced laser scanning applications and/or high material throughput throughout production, scanning systems with more than one scanhead are utilized. Below the software program needs to manage what is done precisely within such a multihead application: it is feasible that all available heads have to mark the very same to complete processing much faster or that the heads note one single work in parallel where every scanhead executes a part of the task in instance of large working areas

In these devices, a semiconductor laser beam of light is usually click to read scanned with the help of a powerful mirror scanner. The mirror is driven electromagnetically and is made from a metal-coated polymer. When a space copyright needs to dock to the room station, it must very carefully maneuver to the proper setting. In order to identify its relative setting to the area station, laser scanners constructed right into the front of the room copyright check the shape of the room station and after that figure out, via a computer, the maneuvering commands.

The usages simply noted which are just a tiny tasting of laser scanning applications have extensively varying technical requirements. This includes parameters like scanning rate, the dimension of the location or volume that must be covered, the laser power involved, the cost, size, dependability, and lifetime of the scanner, and a lot a lot more.

An Unbiased View of Laser Scanning Solutions, Llc.

Depending on the nature of the task, galvanometer scanners are commonly utilized in pairs. This makes it possible for the laser light beam to get to any type of point in a plane.

Dating back to 1960, when Theodore Maiman invented the very first laser, this kind of light has actually evolved right into a device utilized across industries. From clinical therapy to production handling, the power of lasers is utilized across a myriad of sectors and for many kinds of applications. When most think about lasers, the ubiquitous traffic signal lasers typically come to mind.

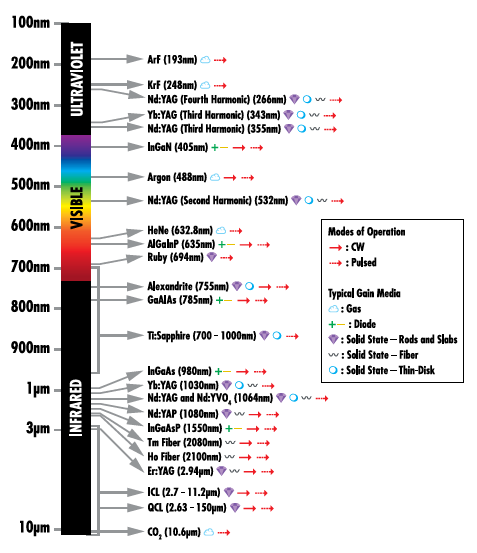

There are over 8 types of lasers across 3 categories! In this blog, we'll discover each classification of laser, what the classification involves, uses for lasers, and eight various kinds of laser makers that compose these groups - bim modeling. Light wavelength distribution map Solid-state lasers are sorts of lasers that use a strong product as its gain tool.

What Does Laser Scanning Solutions, Llc. Do?

When a laser diode shines light on the doped material, the neodymium atoms are thrilled and produce light. This light is then magnified by the product and released as a laser light beam. YVO4 calls for huge amounts of energy to generate a stable high-output power amount. This tool has actually lately taken control of in popularity contrasted to YAG tools.

Gas lasers are utilized for machining and marking applications like marking tags, engraving plastic and materials, handling, and cutting. These laser types use gas as the tool instead of a solid or liquid. The 4 sorts of gas lasers are CO2, He-Ne, excimer, and argon. CO2 gas lasers have the lengthiest wavelength contrasted to fiber, YAG, and YVO4.

Since of the long wavelength, there is even more warm transfer than other lasers. Carbon dioxide lasers are typically made use of for cutting materials.